manganese processing, preparation of the ore for use in various products. Manganese (Mn) is a hard, silvery white metal with a melting point of 1,244 °C (2,271 °F). Ordinarily too brittle to be of structural value itself, it is an

2016年4月27日 The crushing and sampling plant is designed to operate on a one shift per day basis with a capacity of from 400 to 500 tons per shift.

2023年2月27日 Overall, crushing manganese ore is an important step in the production process, as it helps to facilitate transportation, improve processing efficiency, and

The following is a detailed process flow introduction. crushing. The raw materials of manganese ore are uniformly and continuously sent to the PE-750×1060 jaw crusher for

2022年8月15日 The complete processing flow of manganese ore mainly includes five steps: crushing, washing, grinding, dressing, and drying. Next, I will introduce the

2019年11月13日 Strong magnetic separation process. Manganese ore belong to weak magnetic mineral (specific susceptibility X=10×10-6~600×10-6cm3/g), which can be

2015年12月26日 Crushers for large giant process plants >2,000 to 200,000 TPD using semi-autogenous mills only require The Compressive Strength of rocks is measured by crushing cylinder shaped (drill core) ore samples

2019年7月2日 The technological process of dealing with manganese oxide ore is generally crushing the ore to 6 ~ 0 mm or 10 ~ 0 mm, then classification, jigging at the coarse level and shaking at the fine level.

2023年1月13日 13 Jan 2023; Manganese ore crushing process. The crushing of manganese ore is generally a three-stage crushing process: large pieces of manganese

According to the characteristics and main uses of manganese ore, its processing technology mainly includes three processes: crushing, grinding and beneficiation. Specifically: the

2017年3月4日 Ore, Copper Ore, Zinc Ore and Manganese Ore. 4.1 The art of crushing: Crushing means different things for differe nt operations and the production goals are not alway s

2022年11月30日 This kind of manganese ore beneficiation process mainly adopts the combination of gravity beneficiation process and magnetic separation, jigger and strong magnetic separator for joint separation of manganese ore. Therefore, the crushing process plays the role of mineral enrichment in the manganese ore beneficiation

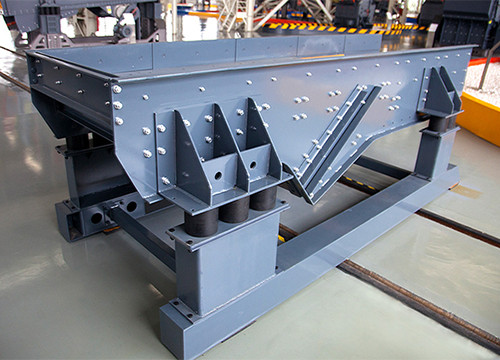

2023年3月2日 Manganese gravity separation process flow: the raw ore enters the silo, is broken into a rough jaw crusher through a belt conveyor, and then enters the fine crusher for secondary crushing. After two crushed ores, the ore is basically free of large stones. The vibrating screen is screened. The crushed ore is divided into two grades of 0-8mm and

2020年11月21日 @article{Mengen2020APF, title={A process for beneficiation of low-grade manganese ore and synchronous preparation of calcium sulfate whiskers during hydrochloric acid regeneration}, author={Lei Meng'en and Bao-zhong Ma and Dongya Lv and Chengya Wang and Edouard Asselin and Yong-qiang Chen},

2021年6月23日 The process of processing manganese oxide ore mainly includes three processes of crushing, grinding and beneficiation. After the primary crushing, the manganese ore blocks are sent to the cone crusher by the belt conveyor for medium and fine crushing until the crushed particles meet the feed demand of the mill used in the next

2016年9月1日 Crushing Silver Ore. Mine ore of a maximum size of 12 in. is reduced to 7/8 in. by one gyratory and two cone crushers, between which are grizzlies and vibrating screens. McClusky Process. Manganese is

2017年1月15日 Manganese ore crushing process. Chunks of manganese ore by silo are evenly sent to first crushing (jaw crusher) for primary crushing by the vibrating feeder, manganese ore coarse crushing by belt conveyor to the secondary crushing (Impact crusher or conecrusher) for further crushing;Manganese ore after crushing is sent into vibrating

2023年1月12日 The processing process of manganese ore mainly includes crushing, screening, flotation, sand washing and dehydration. After processing, manganese ore can generally be used in some chemical and national defense, aerospace and other fields. These fields have relatively high requirements for sand, so the processing process of

2021年2月15日 In the manganese ore roasting process, the air requirement is lower than that of DRI making mainly due to lower carbon consumption to attain the desired temperature. Lab-scale studies were carried out by crushing all the >3 mm fraction in the products and these were processed using a magnetic separator at different operating

2017年3月4日 Ore, Copper Ore, Zinc Ore and Manganese Ore. 4.1 The art of crushing: Crushing means different things for differe nt operations and the production goals are not alway s

The following is a detailed process flow introduction. crushing. The raw materials of manganese ore are uniformly and continuously sent to the PE-750×1060 jaw crusher for preliminary crushing; then the coarsely crushed manganese mineral materials are sent to the PEX-250×1000 jaw crusher by the belt conveyor. a semi-closed circuit

2020年3月6日 The process of processing manganese oxide ore is generally crushing the ore to 6-0mm or 10-0mm, and then classifying, coarse grade particles are sent to jig sorting, and fine grade particles are sent to shaker for sorting. 3. Strong Magnetic Separation Method. Manganese mineral is a weak magnetic mineral (specific magnetic susceptibility

2022年11月30日 This kind of manganese ore beneficiation process mainly adopts the combination of gravity beneficiation process and magnetic separation, jigger and strong magnetic separator for joint separation of manganese ore. Therefore, the crushing process plays the role of mineral enrichment in the manganese ore beneficiation

2023年1月13日 13 Jan 2023; Manganese ore crushing process. The crushing of manganese ore is generally a three-stage crushing process: large pieces of manganese ore are evenly sent to the jaw crusher or coarse crushing mobile station through the silo by the vibration feeder; The coarse crushed manganese ore is screened by vibrating screen

2020年11月21日 @article{Mengen2020APF, title={A process for beneficiation of low-grade manganese ore and synchronous preparation of calcium sulfate whiskers during hydrochloric acid regeneration}, author={Lei Meng'en and Bao-zhong Ma and Dongya Lv and Chengya Wang and Edouard Asselin and Yong-qiang Chen},

19 小时之 How to process iron manganese ore? The processing of iron manganese ore involves several steps to separate the two minerals and produce a concentrated product that can be used in various industrial applications. Here is a general overview of the typical process: 1. Crushing: The ore is first crushed into small pieces using crushers. This helps

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين